National product under development for soldering SMT

favoring the use of derivatives of natural raw materials.

Lead-free alloy SAC 305 (SnAg3.0Cu0.5)

– Type 4 (20-38 microns)

– Flux ROL0, “no clean”

– Halogen-free

– 88.5% metal content

Flux and solder paste

The electronics industry has undergone significant transformations over the years, in the past the focus was on soldering wire and wave soldering technique. However, with the advancement of technology, new demands have emerged, especially in relation to fluxes and solder pastes.

Aware of these changes and the opportunities that arise, Nevex decided to undertake an expansion strategy, both in the national and international markets, with an emphasis on electronics and microelectronics. To achieve this objective, the company developed the New Soldex project in partnership with Science 351 and co-financed by the Compete 2020 program, lasting 3 years.

The Project New Soldex project aimed to develop the first Portuguese solder paste, specifically a “no-clean” solder paste, classified as ROL0 according to the IPC-J-STD-004 standard and without halogen.

Solder paste is the combination of a deoxidizing flux and metal powder. Currently, the most used alloy for solder paste is SAC305, composed of 96.5% tin, 3% silver and 0.5% copper. The metal powder is characterized by its spherical particle size distribution, with Nevex opting for T4 type powder, with particle sizes between 20 and 38 µm.

Flux

Solder Paste

SAC305 has been widely used and is well defined in the literature, as such, the NewSoldex project focused on the development of the deoxidizing flux. During these three years of development, 80 raw materials were tested, with preference given to the use of raw materials derived from natural products. During development, around 350 formulations of deoxidizing fluxes were produced, creating a prototype that was used to produce solder paste.

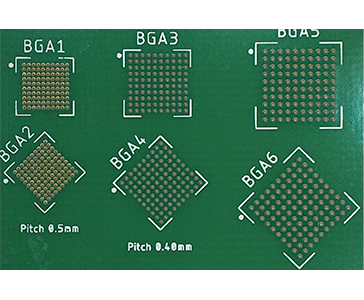

To test the solder paste, test boards were designed containing patterns of the most common components and also specific patterns, in different orientations and sizes, thus allowing the performance of the solder paste to be evaluated. Around 300 printing tests and 120 soldering tests were carried out to guarantee the performance of the solder paste.

Test boards

Prints with well-defined solder paste deposits and adequate amounts of paste.

Solder joints with excellent metallic appearance and regular shape and well adjusted to the pads

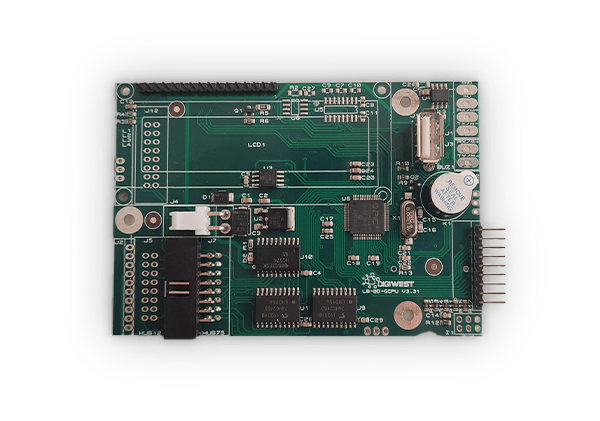

The positive results obtained with the test boards led to the prototype being tested on functional printed circuit boards, supplied by the company Digiwest, which showed excellent results. In total, 52 boards were produced, and only a small soldering defect was detected, a short circuit between two pads of an integrated circuit chip.

Board soldered with the prototype

Solder joints with solder paste from Nevex

Display with board soldered with Nevex prototype

Some results from the project New Soldex project were shared through an article in issue no. 127 of the "Robótica" magazine, as well as a poster presented during the “Coimbra Chemistry Center Day 2021” congress in partnership with Science 351.